“The Goal” is a management-oriented novel that uses a narrative to introduce the Theory of Constraints, a method to improve organizational performance and achieve strategic goals.

What is the theory of constraints?

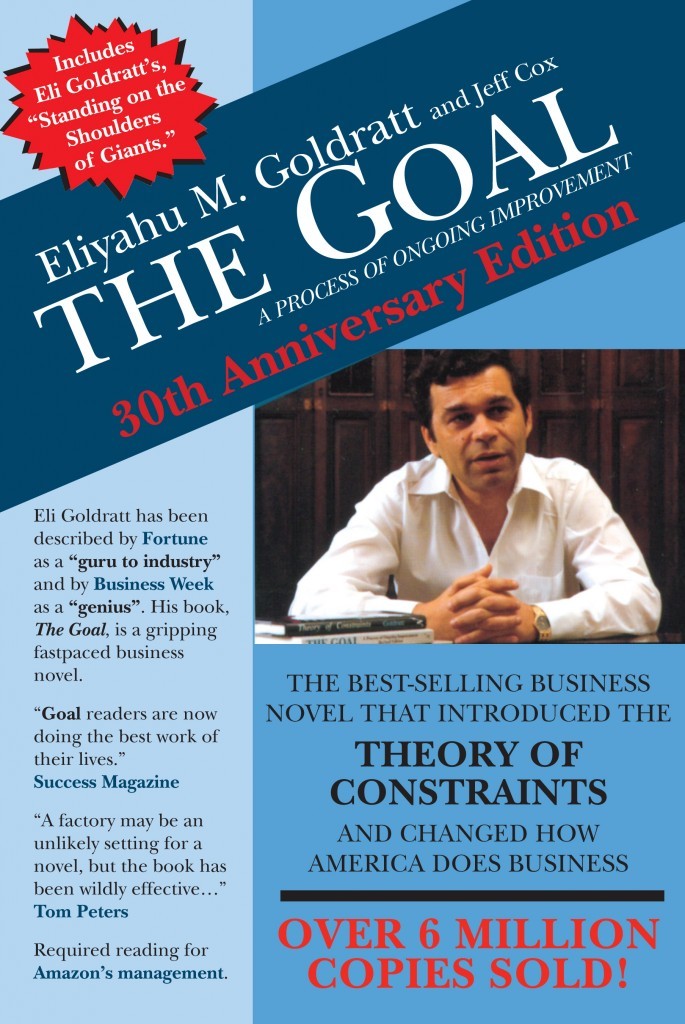

“The Goal” by Eliyahu M. Goldratt and Jeff Cox is a seminal book that presents the Theory of Constraints (TOC) through the story of Alex Rogo, a plant manager struggling to save his manufacturing plant and his marriage. Facing closure, Rogo, with the help of his mentor Jonah, discovers the fundamental principles of managing bottlenecks, improving productivity, and achieving operational excellence. The book is a masterclass in understanding and applying the principles of TOC to not just manufacturing processes but to any challenge requiring systematic problem-solving. It emphasizes the need to identify and address the single constraint that limits the achievement of higher goals. Through Rogo’s journey, readers learn valuable lessons on teamwork, leadership, and the importance of continuous learning and improvement in both professional and personal life.

A book review would likely commend “The Goal” for its innovative approach to presenting complex business concepts through a relatable narrative, making it accessible and engaging for a wide audience. It’s praised for its clear explanation of how to improve organizational performance by focusing on constraints, its insights into operational efficiency, and its profound impact on management thinking. The novel’s practical approach to solving business problems has made it a must-read in the fields of operations management and business strategy.

The 10 main points learned from “The Goal” include:

- Theory of Constraints (TOC): The core concept of focusing efforts on improving the system’s bottleneck to enhance overall performance.

- Identify the Constraint: Recognize the system’s limiting factor that prevents achieving higher performance.

- Exploit the Constraint: Optimize the bottleneck’s performance without additional costs.

- Subordinate Everything Else: Align all other processes to support the improvement of the bottleneck’s performance.

- Elevate the Constraint: If necessary, take actions to increase the capacity of the bottleneck.

- Repeat the Process: Continuously identify and address new constraints as they emerge.

- Throughput, Inventory, and Operational Expense: The three key metrics for measuring the health and efficiency of a manufacturing operation.

- Batch Size Reduction: Reducing batch sizes to improve flow and reduce lead times.

- Collaboration Across Departments: Emphasizing the importance of interdepartmental communication and cooperation.

- Continuous Improvement: The ongoing effort to improve products, services, or processes to enhance competitiveness and efficiency.

Some impactful quotes from “The Goal” include:

- “The goal of a manufacturing organization is to make money.”

- “An hour lost at a bottleneck is an hour lost for the entire system.”

- “Inventory is all the money that the system has invested in purchasing things which it intends to sell.”

- “Operational expense is all the money the system spends in order to turn inventory into throughput.”

- “Throughput is the rate at which the system generates money through sales.”

- “You can only be efficient relative to your goal.”

- “Improvement is not doing more things right, but doing less things wrong.”

- “Technology can bring benefits if and only if it diminishes a limitation.”

- “A system of local optimums is not an optimum system at all.”

- “The closer you get to a goal, the more constraints you will identify.”

For those interested in further exploring similar concepts, related books include:

- “Critical Chain” by Eliyahu M. Goldratt, which applies TOC principles to project management.

- “Lean Thinking” by James P. Womack and Daniel T. Jones, offering insights into lean manufacturing and how to create more value with less work.

- “The Toyota Way” by Jeffrey Liker, detailing Toyota’s management philosophy and practices.

- “Factory Physics” by Wallace Hopp and Mark Spearman, which provides a comprehensive look at the science of manufacturing and operations management.

These books complement the ideas presented in “The Goal,” offering readers a broader understanding of operational excellence, efficiency, and continuous improvement across various domains.